Company History

The Process Begins

- 1949 The future Mrs A.R. Billington starts work for the Decca Record company London.

- 1963 Mr C St John Stevens and Mr J.S Billington form Stevens & Billington Ltd.

- 1986 Mr J G Billington graduates with a degree in Electronics and Communication Engineering.

- 2002 Mr J G Billington ( BSc Hons ) forms Music First Audio Limited.

- 2003 ” the best pre amplifier ever made ( Hi-Fi World) ”.

- 2005 The awards begin to flow.

The steel ruler in the picture to the left has been used in the manufacture of transformers by the Billington family since 1963. It is still used every working day.

6 decades of experience resulting in transformer and audio excellence.

Location

Music First Audio is based in Rye, East Sussex on the South Coast Of the UK.

Company

Music First Audio is owned completely by Mr Jonathan Billington of Stevens & Billington Limited (www.stevens-billington.co.uk) a small, specialist audio transformer winding business formed in 1963 by Mr Stevens & Mr Billington. The company produced transformers and other wire wound components for the professional audio, broadcast and Hi Fi industries.

Jonathan Billington took over the family business in 1986 having finished Polytechnic with a degree in electronics and communications engineering (specialising in acoustics) and a deep rooted love of music. He set about improving the quality of the product and Stevens & Billington Limited was soon able to count The BBC, Soundcraft, The Royal Opera House, The House of commons and countless other highly respected organisations among it’s customers.

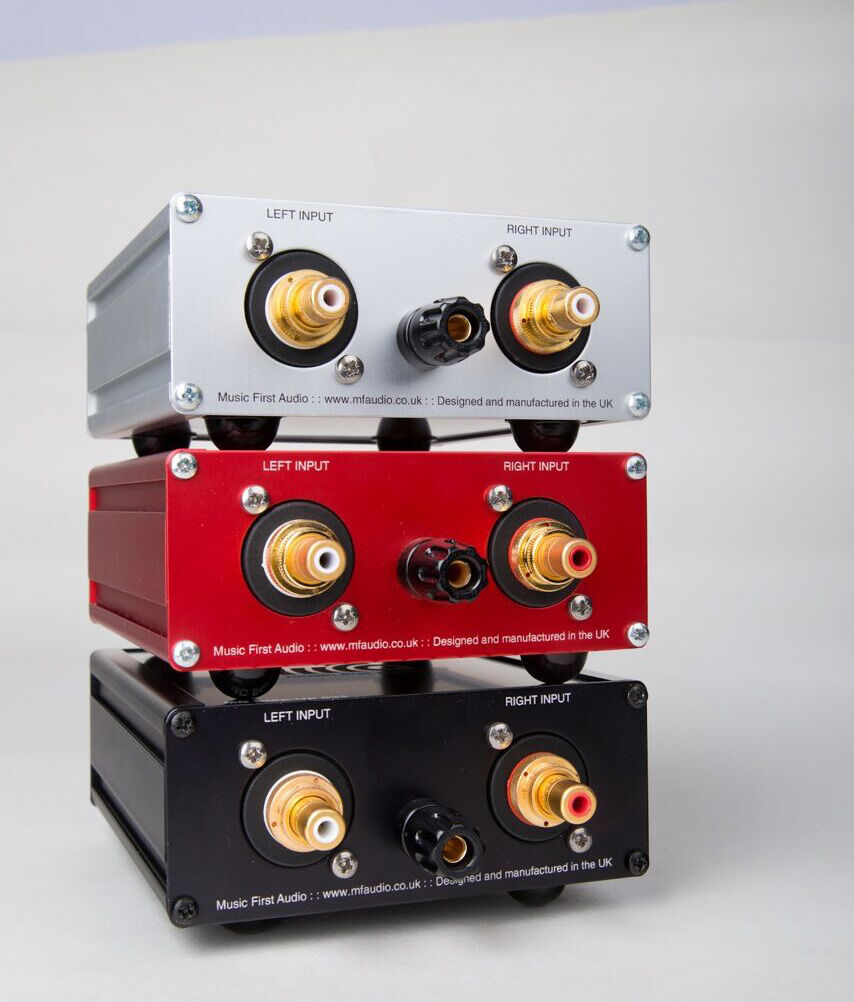

Stevens & Billington Limited (and Music First Audio) comprises a small but highly skilled and dedicated team who share a passion for music and a devotion to excellence. The TX 102 transformer which lies at the heart of the Music First Audio preamplifier is the result of 40 plus years of transformer design focused on one product. It is the fruit of almost three months of constant redesign and perfection where listening test and measurement followed adjustment after adjustment as the final product was honed for it’s purpose.

The design process continues to this day